The Perfect Fit:

Why Do CakeBoxx® Containers Make Ideal Equipment Enclosures?

When it comes to housing critical equipment like generators, compressors, and pumps, not all enclosures are created equal. For companies that require robust, portable, and modular equipment housing, the limitations of traditional containers are often very apparent.

Some manufacturers offer turnkey packages for their equipment, complete with integrated lighting, ventilation, and piping, all wrapped up in what might be called a “weatherproof enclosure.” While these packages are convenient, they can have significant constraints, especially when created using modified standard shipping containers.

At CakeBoxx Technologies, we believe in delivering solutions that not only meet but exceed industry standards, offering truly innovative containers that are engineered to meet all of the customer’s requirements without limitation.

Where Standard Containers Fall Short

Modifying existing shipping containers might seem like a cost-effective solution, but it’s far from ideal in many cases. Alterations like adding doors, openings, or reinforcement can void the container’s ISO and CSC certifications, making them unfit for standard intermodal shipping methods. Not to mention, these modifications often lead to structural weaknesses, requiring additional costly reinforcements. In the end, you’re left with a container that’s neither cost-effective nor fully compliant with industry standards.

CakeBoxx: Built from the Ground Up

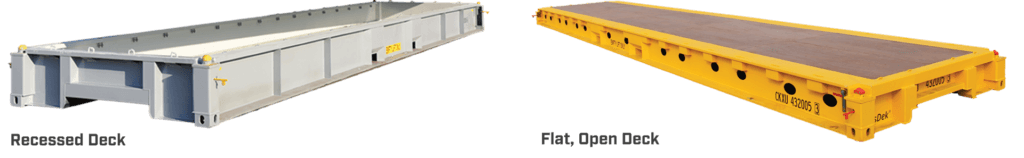

At CakeBoxx Technologies, we take a different approach. Rather than attempting to retrofit existing containers, all of our containers and platforms are engineered from the ground up.

They are specifically designed to meet each of our customer’s unique needs and use cases. This allows us to create solutions that are not only robust and versatile but also fully compliant with all relevant industry standards.

Specialized and Compliant: The CakeBoxx Advantage

One of the critical advantages of CakeBoxx containers is their ability to be tailored to meet even the most stringent industry requirements. From insulation packages to specialized openings and doors, our containers can be tailored to fit the exact needs of your project.

Building for the Future:

Portable, Modular, and Scalable Solutions

The need for portable, modular, and scalable enclosures is growing across industries, from manufacturing to energy production. CakeBoxx Technologies is at the forefront of this trend, offering containers that not only meet current needs but also anticipate future challenges.

The CakeBoxx Difference

As industries evolve, so do the requirements for equipment enclosures. CakeBoxx containers are designed with the future in mind, offering the flexibility needed to adapt to changing needs. Whether your organization is expanding its operations, upgrading equipment, or entering a new market, CakeBoxx containers provide a future-proof solution that can grow with the business.

At CakeBoxx Technologies, we don’t just build containers—we build solutions. Our innovative approach to container design and construction ensures that our products meet the highest standards of quality, compliance, and performance. Whether you’re in need of a portable enclosure for a diesel genset, a modular solution for a hydrogen compressor, or a specialized platform for complex equipment, CakeBoxx has the expertise and technology to deliver.

Stop compromising with modified standard containers and discover how CakeBoxx containers can solve your toughest enclosure challenges.

Contact us today to learn more about our innovative solutions tailored to your exact needs.