Metal Transportation without the Headaches

Transporting metal is a common logistical challenge for shippers. The size, shape, weight, and texture of the metal cargo are among the determining factors in how this challenge is approached and the options available.

Using standard shipping containers would in an ideal world be the most convenient method due to the protection offered by the steel walls, many cost-effective routings globally and easy transloading between sea, road, and rail.

But the world isn’t ideal. Obviously, in many cases the large size of the cargo will immediately eliminate intermodal containers as an option. More complicated and expensive break bulk movements will generally be required.

However, a large amount of metal cargos are shipping break bulk even if they would fit into the volume of a container. This is due to the difficulty and time required in physically loading the materials at the point of origin and unloading at destination. Any customs inspections and destuffing required along the way will also put a considerable wrench in the gears for shippers.

Loading and unloading long metal beams and tubular products into a container for example (where it is even possible), requires a high degree of coordination between at least two forklift drivers to maneuver the cargo through the open doors. Even when this is miraculously achieved without any damage to the cargo or container, there remains the issue of securing the beams for safe intermodal transit. Who wants to climb into a laden container to strap down the cargo? Nobody.

Flat racks are of course a great option for many shippers and CakeBoxx Technologies produces a line of specialized flat racks with collapsible posts to suit many of our customers. But what about the high-value steel and aluminum cargos which are easily damaged or affected by weather? Packaging and tarps go some way to addressing this but there’s still room for a lot of environmental or accidental damage.

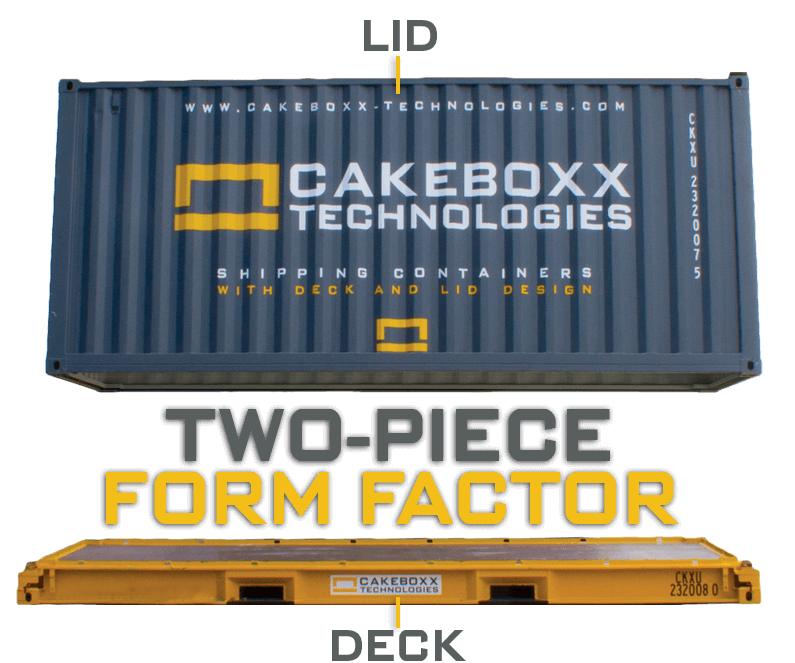

CakeBoxx Technologies’ range of container products with their flat ‘deck’ loading platform and ‘lid’ cover can solve all these issues. They load like a flat rack and ship as a container. You don’t need to destuff a CakeBoxx container either. Customs officials can simply lift the lid and can have full visibility of the entire cargo.

If it’s shipping long metal cargos like re-bar, I-beam, tubular steel, and pipe, the 40ft, 45ft, and 53ft models are well suited.

For smaller cargos like metal sheets and ingots, the 20ft CakeBoxx models are a great option. The ShortBoxx 20ft container is a half-height CakeBoxx, which can be safely and efficiently stacked; maximizing product haulage potential with the same footprint as a standard container.

Cold-rolled steel coils are notorious for their sensitivity and need to be protected from moisture. Blocking and bracing these in a container, however, is a costly and time-consuming process. New for 2019, the CoilBoxx 20ft model is revolutionizing the world of coil shipments. Its deck includes cradles adjustable to accommodate up to three coil ODs, as large as 1700mm and as small as 300mm with a maximum width of 2232mm. Coils can be easily secured without the need for blocking and bracing or any further packaging using the embedded tie-down system.

Whatever the metal cargo, CakeBoxx containers have your back.