A Deep Dive into Container Solutions:

Navigating the Complexities of Lithium-Ion

Battery Storage and Transportation

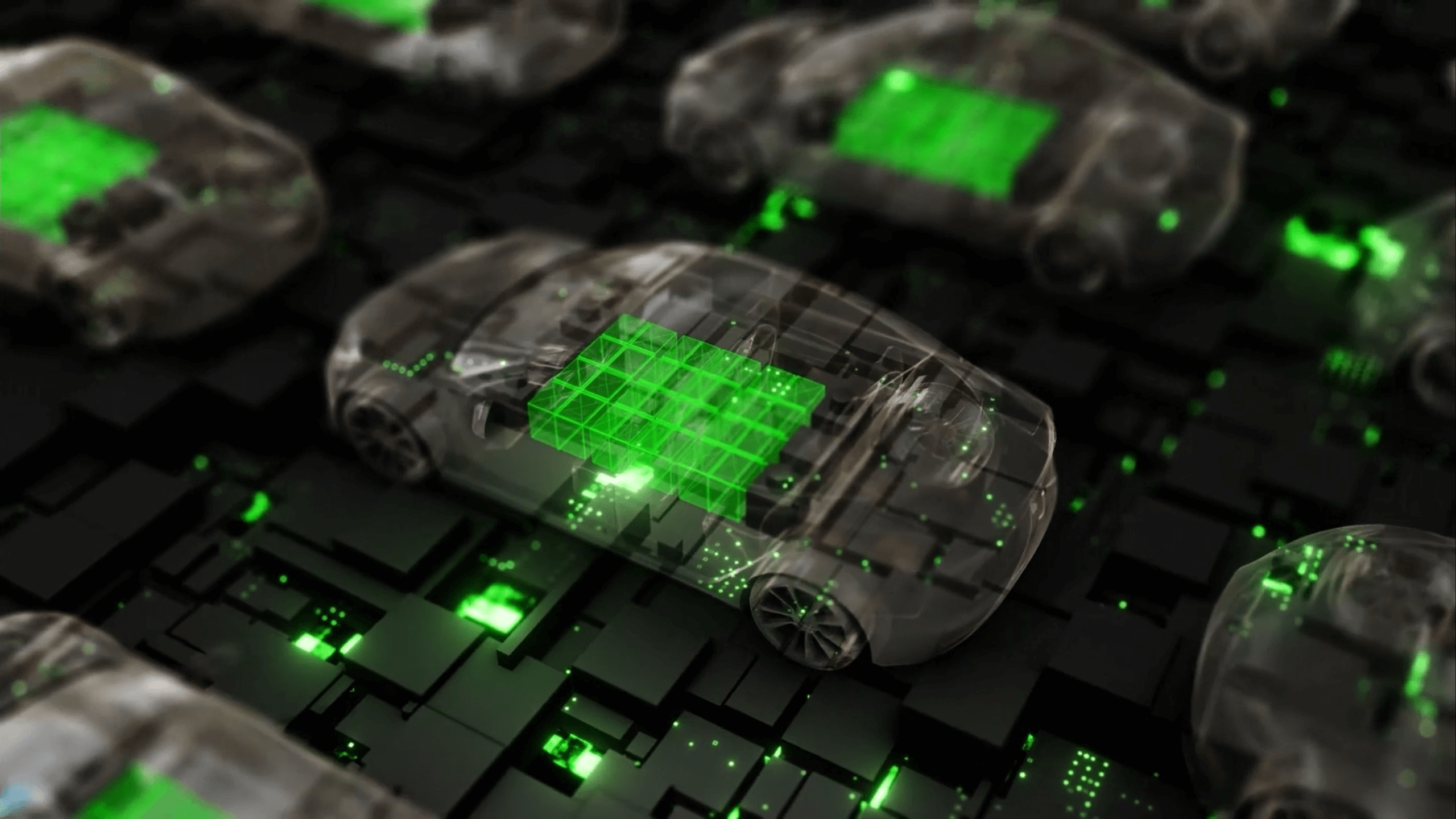

Lithium-ion batteries power many of the devices and technologies that define the modern world – from smartphones to electric vehicles. However, with the proliferation of these energy sources comes a complex set of challenges, particularly regarding their storage and transportation. As industries ranging from automotive to aerospace rely more heavily on lithium-ion batteries, the need for safe and efficient methods of handling these batteries has never been more critical.

The Storage Challenge:

Balancing Safety, Longevity, and Scale

Storing lithium-ion batteries isn’t simply about finding space; it’s about ensuring that space is optimized for safety and longevity. These batteries are sensitive to external factors (potential shock/damage) and temperature extremes, both high and low, which can degrade their performance or even cause safety issues. Ideal storage conditions are cool, dry, and stable. Just like a fine wine, where fluctuations in temperature or humidity can ruin the product; however, unlike wine, improper storage of lithium-ion batteries can lead to catastrophic failures, including fires and explosions.

Temperature isn’t the only concern. The state of charge (SoC) plays a pivotal role in storage. It might seem logical to store batteries fully charged, but this increases stress on the cells, leading to faster degradation. Conversely, storing them fully drained can be equally damaging. Maintaining an optimal SoC—a manufacturer-specified “sweet spot”—across hundreds or thousands of batteries becomes a logistical challenge that demands meticulous planning and oversight.

These storage challenges multiply when scaled up to an industrial level, as seen in industries like energy, aerospace, defense, or automotive. Storing large quantities of batteries requires not just space but sophisticated infrastructure to manage temperature, humidity, and SoC levels effectively.

Transportation:

Walking the Tightrope of Regulation, Risk, and Innovation

Transporting lithium-ion batteries is a high-stakes operation, governed by stringent regulations. These regulations exist for good reason: mishandling lithium-ion batteries can turn them into serious fire hazards. From ensuring compliance with the United Nations UN 38.3 tests to using proper packaging that makes short circuits less likely, every step in the transportation process is tightly controlled. However, these regulations are only part of the solution; the real challenge lies in consistent implementation across the global supply chain.

Innovative Solutions to a Growing Problem

The need for innovative solutions in lithium-ion battery storage and transportation is clear. The industry is exploring several avenues to address these challenges:

Thermal runaway from lithium-ion batteries is a problem that industries are working to find solutions for.

Looking to the Future

As industries continue to innovate with lithium-ion batteries and future battery technologies, the pressure to solve storage and transportation challenges will only grow. Whether through more robust packaging solutions, enhanced safety protocols, or the development of alternative battery technologies, the need for innovative solutions is undeniable.

The work being undertaken by companies like CakeBoxx Technologies shows that the industry is moving in the right direction. By focusing on both prevention and mitigation, we can ensure that the benefits of lithium-ion batteries are realized without compromising safety. The road ahead is challenging, but with continued innovation and collaboration, we can navigate the complexities of lithium-ion battery storage and transportation more effectively.

The Imperative for Safety and Innovation

The transportation and storage of lithium-ion batteries are at a critical juncture. The risks are well-documented, and the need for innovative solutions is urgent. As the industry continues to expand, the importance of safe, efficient, and sustainable practices cannot be overstated. With advancements in container design and a renewed focus on safety, we can mitigate the risks associated with lithium-ion batteries and pave the way for a more electrified and sustainable future.

Contact CakeBoxx

To find out more about how CakeBoxx Technologies can help you containerize lithium-ion batteries or any other high-value, high-consequence cargos, simply provide your contact information and we’ll look forward to discussing your needs: